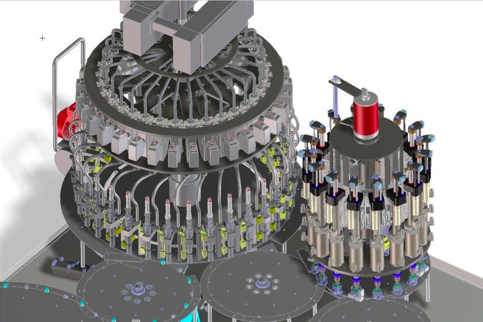

Optima Consumer present the OptiPouch system with first-time fully automated feeding of the containers into the machine. The combination of the new rotary filling machine and the rotary closing machine creates a complete, continuous process. The OptiPouch system processes up to 600 spouted pouches per minute. This corresponds to an increase of 250 percent compared to the fastest machines to date. Only one operator is needed to provide the machine with prefabricated pouches. Various pouch types and sizes ranging from 50 to 500 ml are processed without the need to change size parts on the machine.

Various options are available to enhance the highly compact system with various hygienic and sterilization functions such as CIP / SIP, laminar flow with Hepa filters, and UV light. As a turnkey supplier, Optima also implements complete solutions including secondary packaging and palletizing. The spouted pouches are excellent in terms of logistics and significantly reduce the CO2 footprint. Approximately 1.8 million empty containers are transported per truckload.

Optima Consumer has also packaging solutions for foods, cosmetics and chemicals. The company’s packaging systems process a wide variety of products from low to high viscosity, powder or granulate, serving-size packages or large containers, including everything from coffee capsules to mascara sticks and even oil canisters.